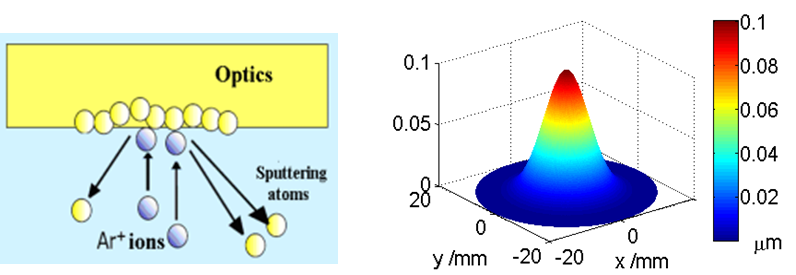

How dose Ion Beam Figuring work?

In a vacuum environment, using an ion beam as a polishing tool, the physical sputtering effect that occurs when the ion beam bombards the surface of the workpiece is utilized to remove surface error material, achieving the purpose of precision shaping.

- High precision, atomic-level material removal.

- High determinacy, stability, and controllability.

- Non-contact processing, user-friendly operation, no edge effects.

- Gaussian-type removal function, good shape, smooth, no machining marks.

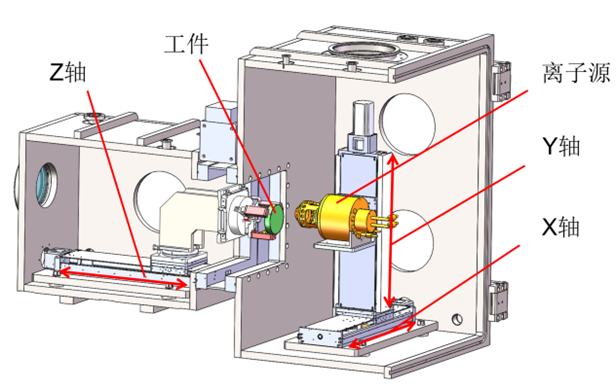

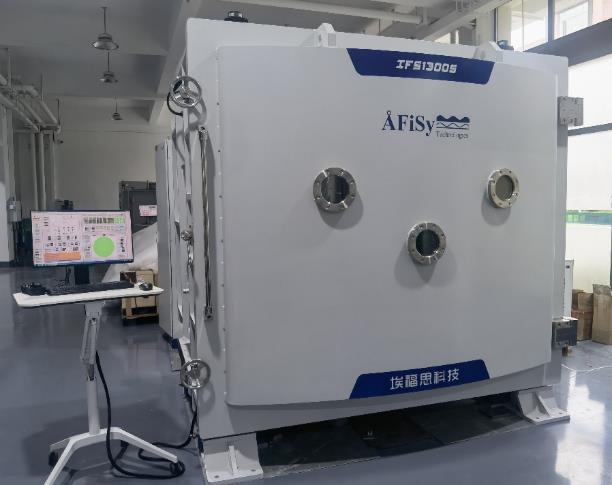

ÅFiSy Ion Beam Polishing Machine Solutions (1/4)

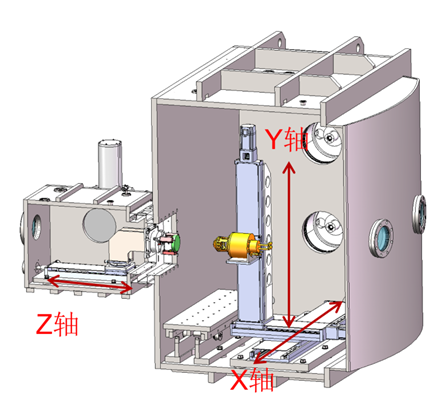

Plan A: Double chamber structure, workpiece vertical entry;

Patent: ZL201811261305.2

- Using the Z-axis for transportation, no special conveying mechanism is required.

- Short workpiece transfer distance and time.

- Structural optimization.

- High reliability.

ÅFiSy Ion Beam Polishing Machine Solutions (2/4)

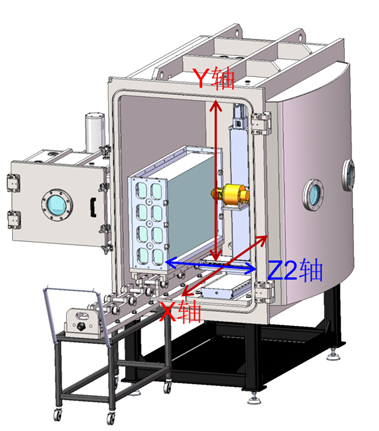

Plan B: Dual-chamber structure, small workpieces are fed vertically from the auxiliary vacuum chamber, and large workpieces are fed vertically from the side of the main vacuum chamber.

Patent: ZL202020687288.5

- Accommodates both large and small workpieces.

- Small workpieces: Retaining the advantages of Plan A, quick changeover, and high efficiency.

- Large workpieces: Operated directly in the main vacuum chamber, simple, safe, and reliable.

ÅFiSy Ion Beam Polishing Machine Solutions (3/4)

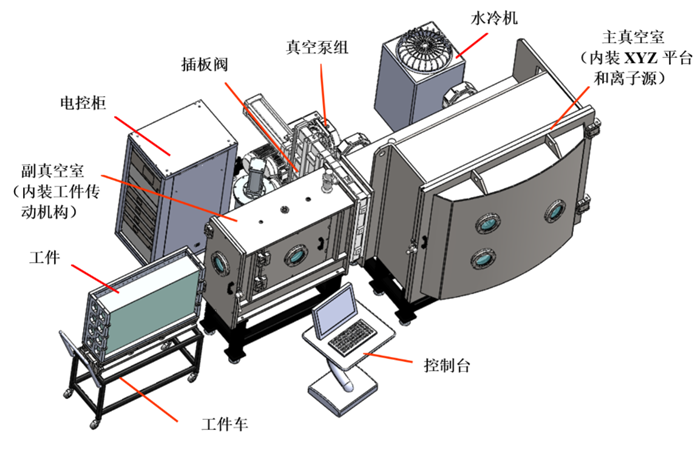

Plan C: Dual-chamber structure, both small and large workpieces are vertically entry from the auxiliary vacuum chamber.

Patent: ZL201910483330.3

- Compared to the vertical straight-through workpiece, the slide valve is smaller, and the auxiliary vacuum chamber is smaller.

- The workpiece uniformly enters and exits from the auxiliary vacuum chamber, resulting in high efficiency and making it suitable for batch processing of large workpieces.

ÅFiSy Ion Beam Polishing Machine Solutions (4/4)

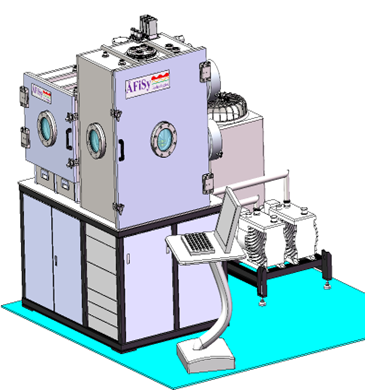

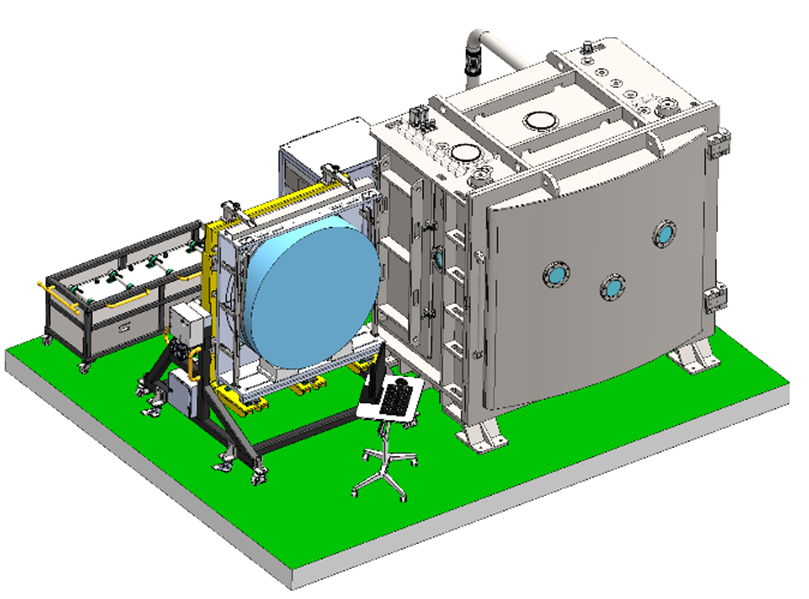

Plan S: Single-chamber structure. Workpieces enter vertically from the side.

- It has a compact structure, occupies a small area and offers a high cost-performance ratio.

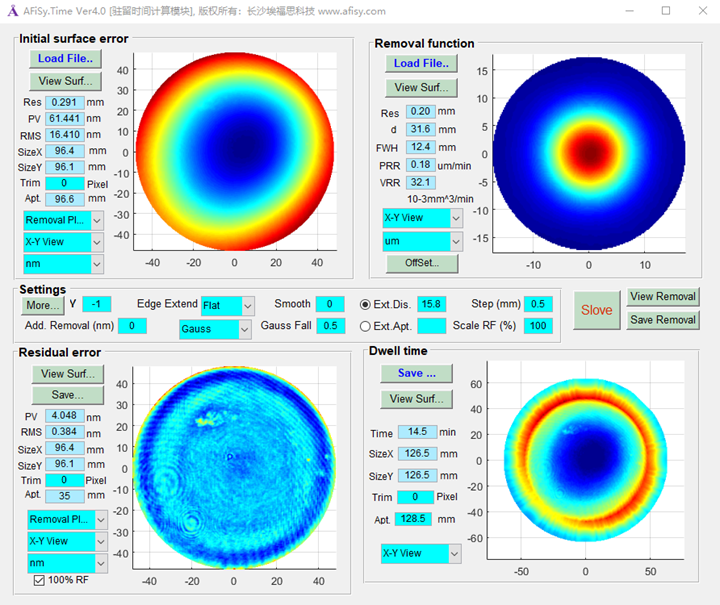

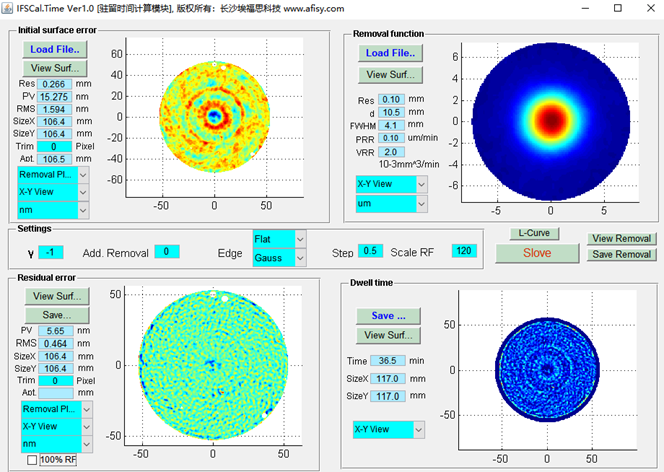

Intelligent process control

Independent intellectual property rights of process calculation software ‘IFSCal’ and process control software ‘IFSCtrl’.

- Fully digital monitoring

- Highly integrated: Integrated control of vacuum, motion, and ion source systems.

- Highly intelligent: Equipped with features such as one-click startup, one-click shutdown, scheduled startup, scheduled shutdown, appointment processing, and processing protection.

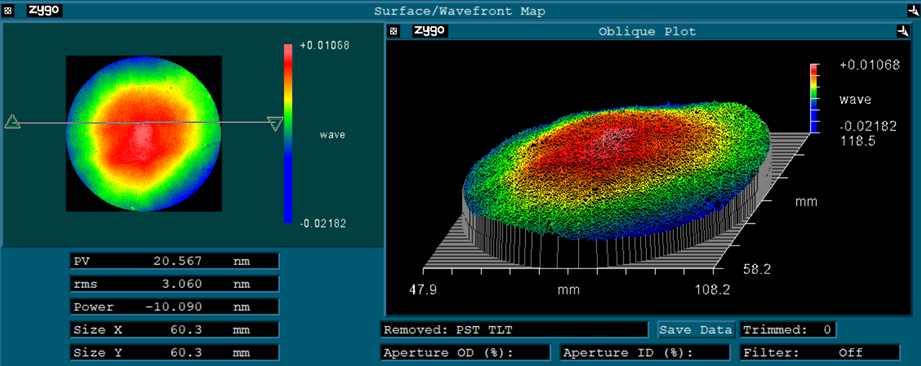

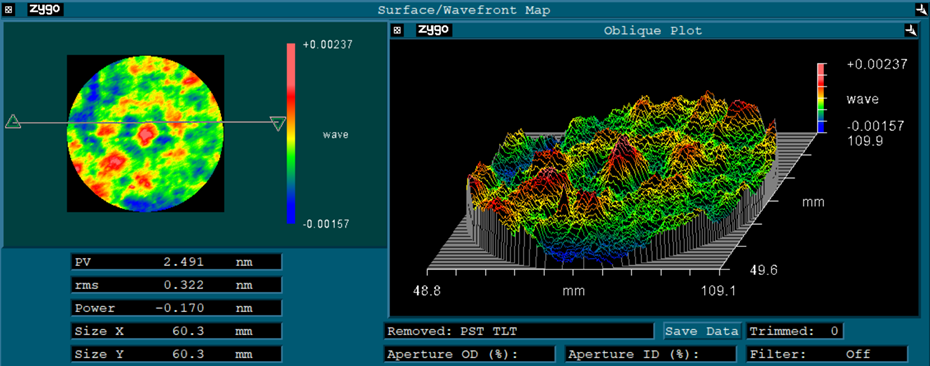

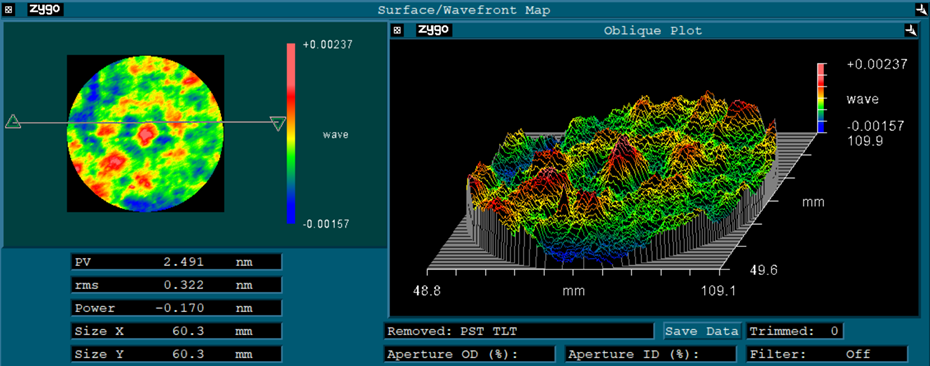

Processing result display 1/3

High precision

Single crystal silicon, 60 mm diameter

Before: 3.1nm RMS/20.6nm PV

5.4min

After: 0.3nm RMS/2.5nm PV

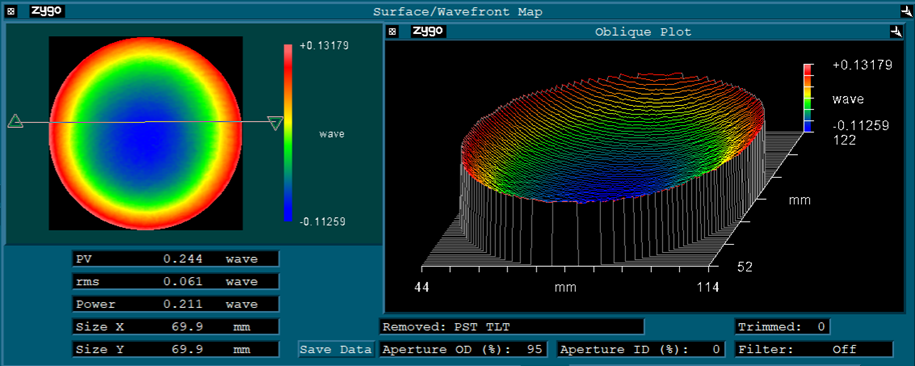

Processing result display 2/3

High certainty

Quartz , 74 mm diameter

Before: 0.061λ RMS(λ=632.8nm)

21min

After: 0.007λ RMS

Single processing convergence ratio:0.061/0.007 = 8.7

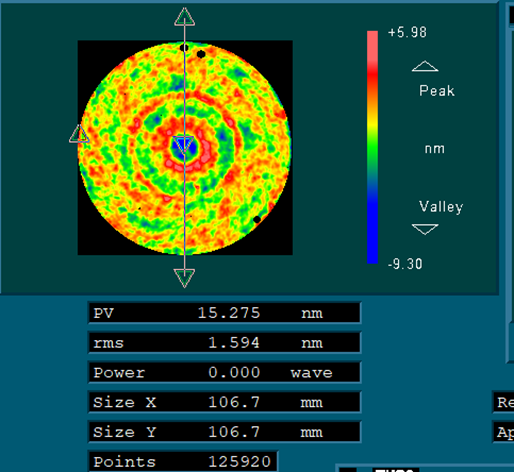

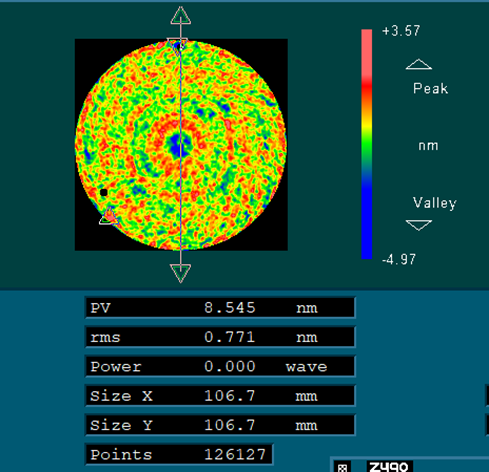

Processing result display 3/3

Mid-high frequency error correction

36.5min

Before: 1.59nm RMS

After: 0.77nm RMS