How dose Magnetorheological finishing work?

Using magnetorheological fluid (made of magnetic particles, base liquid, surfactant as the matrix, and adding polishing powder) as a polishing tool, rheological characteristics are generated under the action of a controllable magnetic field, and a magnetic fluid with controllable viscosity is formed. Surface errors of optical parts are quantitatively removed at fixed points to achieve efficient and high-precision shape modification.

- High-efficiency, low-damage processing

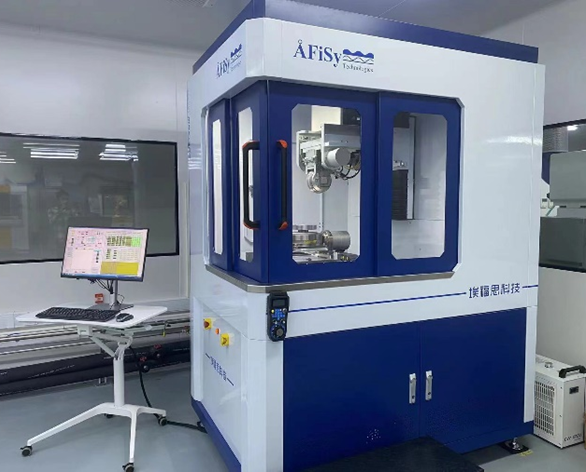

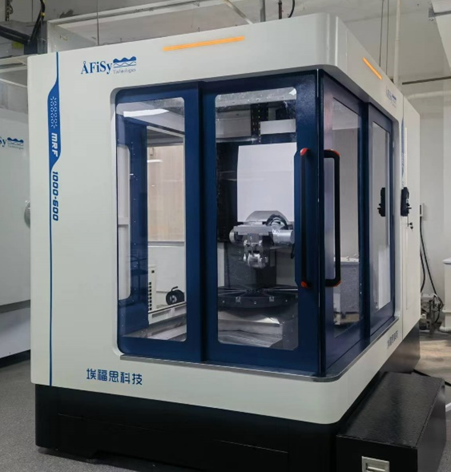

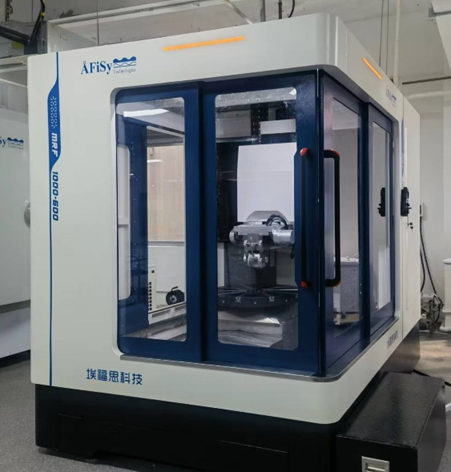

ÅFiSy Magnetorheological Finishing Machine Model

- Five-axis linkage processing, positioning accuracy up to micron level

- Brand new closed-loop control algorithm that compensates for motion errors in real-time across all axes.

- Configure the three-coordinate probe: detect the position of the workpiece in place.

- Three-coordinate/intelligent positioning: use standard spheres and other references to correct mechanical installation errors of each axis.

- Three-coordinate/tool setting: verify workpiece positioning, tool setting, and processing parameters, and perform real-time correction.

Display of processing results.(Plane)

Display of processing results (spherical surface).

Display of processing results (spherical surface).

Material: N5742, Diameter: 155mm, Test Aperture: 148mm, Effective Aperture: 140mm.

Display of processing results (spherical surface).

Material: H-FK61B, Diameter: 80mm, Test Aperture: 80mm, Effective Aperture: 78mm.