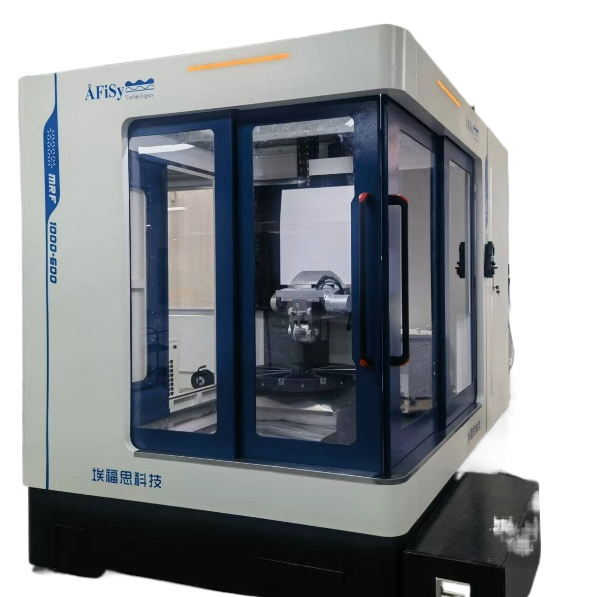

Overview of Magnetorheological Finising Machine MFR1000-600A

The magnetorheological finishing machine ÅFiSy MRF1000-600A uses magnetorheological fluid to polish the surfaces of optical components under the effect of the magnetorheological effect.

Key Features

- The overall structure is made of marble frame. Marble has been buried underground for many years and its structure is quite stable, making it the most ideal bed for high-precision equipment.

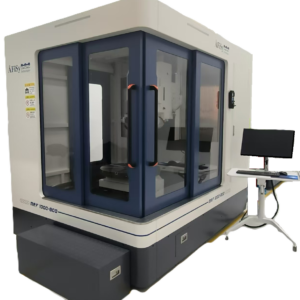

- It has 6 axes and 6 simultaneous movements (X/Y/Z/A/B/C), with multiple processing path modes available, which can adapt to the processing of aspheric surfaces, off-axis surfaces and freeform surfaces.

- Self-developed high-performance magnetorheological polishing fluid, which offers high cost performance and long-term stability.

- Motion control technology with independent intellectual property rights enables precise control of the dwell time and achieves higher polishing precision.

- The calculation software integrates various advanced algorithms, such as the L-curve algorithm for determining the optimal processing amount and the optimal edge continuation algorithm (smooth descent continuation method).

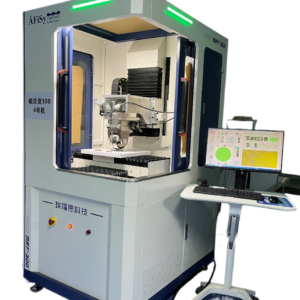

- Equipped with a coordinate measuring probe, which is used for workpiece position detection and surface shape detection, making operations like workpiece tool setting very convenient, efficient and intelligent, while also having higher precision.

- The calculation software provides a processing analysis module that can conduct comparative analysis on the processing results and simulation results. It can analyze the removal function errors and positioning errors during processing, thus improving the certainty and processing precision of subsequent processing.

- The control software is highly integrated, realizing full digital monitoring, information sharing among various monitoring systems, having functions like log function and handwheel function.

Why Choose This Machine?

This high-precision Magnetorheological Finising Machine not only enhances productivity but also guarantees a quality finish. With its robust construction, it is tailored for both commercial and scientific research purposes, making it a valuable addition to your equipment lineup.

Attributes

| name | parameter |

| Processing Capabilities (Maximum workpiece size) | Maximum size 1000mm×600mm |

| Machinable surface | Plane, spherical, aspherical, etc. |

| Processable materials | Microcrystalline, K9, fused quartz, Si, CVD, SiC, nickel-phosphorus layer, etc. |

| Machinable accuracy | |

| X-axis travel | 1050mm |

| Y-axis travel | 700mm |

| Z-axis travel | 350mm |

| A-axis travel | ±45° |

| B-axis travel | ±35° |

| C-axis travel | n×360° |

| Fixture | / |

| Protection function | It has fault alarm protection for unexpected power failure, water failure, gas failure, motion system failure protection, etc. |

| Smart Features | It has advanced functions such as appointment timing, processing protection, remote assistance, and logs. |

| Dimensions | 2.7m×1.8m×2.3m |

| Machine weight | 10 tons |

| Power consumption | 15 KW |

Reviews

There are no reviews yet.